Striving to better ourselves , CMC Mercedes-Benz 600 Pullman Landaulet with functional soft-top

Thanks to the enthusiastic encouragement and support of our customers, CMC has celebrated its 25th anniversary. In response to customer’s heart-warming anticipations, we have subscribed to the motto: Keep improving what we are doing to the best of our ability — one product at a time. A good case in point is M-205, the CMC Mercedes 600 Landaulet. We would like to share with you some of its functional highlights and our joy over the achievement of transcending ourselves and technical difficulties to make these functions possible.

The Mercedes 600 Landaulet is a well-known means of carriage for dignitaries, including national heads and elite officials as they stand or sit in the open-top passenger compartment to receive accolade from the honor guards or cheering crowds. The folded soft-top, in this case, rests behind the back seats.

When CMC started to develop this replica in 2018, it touched off a heated debate within the company: Was the soft-top going to be functional? Or just symbolically replicated? A symbolic replication of the soft-top was not a problem. During our development of the Ferrari California Spyder in 2012, attempts were made to develop a truly convertible canopy. In fact, the hardware of its metal bracket was completed, but it didn’t work well with the fabric top. Once mounted on the metal bracket, the canopy would not fold compactly enough for the soft-top to be truly retractable.

In developing a soft-top for the CMC Mercedes-Benz 600 Landaulet, however, it was not only required that the fabric canopy could be freely opened and folded, but also that the rear window would follow suit without affecting the folding function. In addition, the edges of a fully-spread soft-top should be aligned with the tops of the closed doors, and no apparent crevice was detectable. These would be the goals that we set out to achieve.

Following the debate, preparations were made for two different approaches. One was for symbolic replication of a soft-top without functions — a safe but undesirable approach. Another was to take on the challenge by overcoming seemingly insurmountable difficulties to come up with an innovative process that enabled the canopy to become functional.

To begin with, a metal bracket was developed to provide the convertible framework for the canopy. The rear widow, however, posed a serious problem that interfered with the folding of canopy consistently. We spent a lot of time tackling this difficulty and tried many different solutions until it was finally surmounted!

Last but not the least, it was important that the bracket gave the right support and shape to the soft-top so that it was in line with the overall configuration of the car. To this end, we had to repeatedly modify the bracket design.

In retrospect, production of the close-top versions of the CMC Mercedes-Benz 600 was completed in 2020. It was followed by the manufacturing of the CMC Mercedes-Benz SSK series of products – an arrangement that gained more than 8 months for the development of a functional soft-top for the CMC Mercedes-Benz 600 Landaulet.

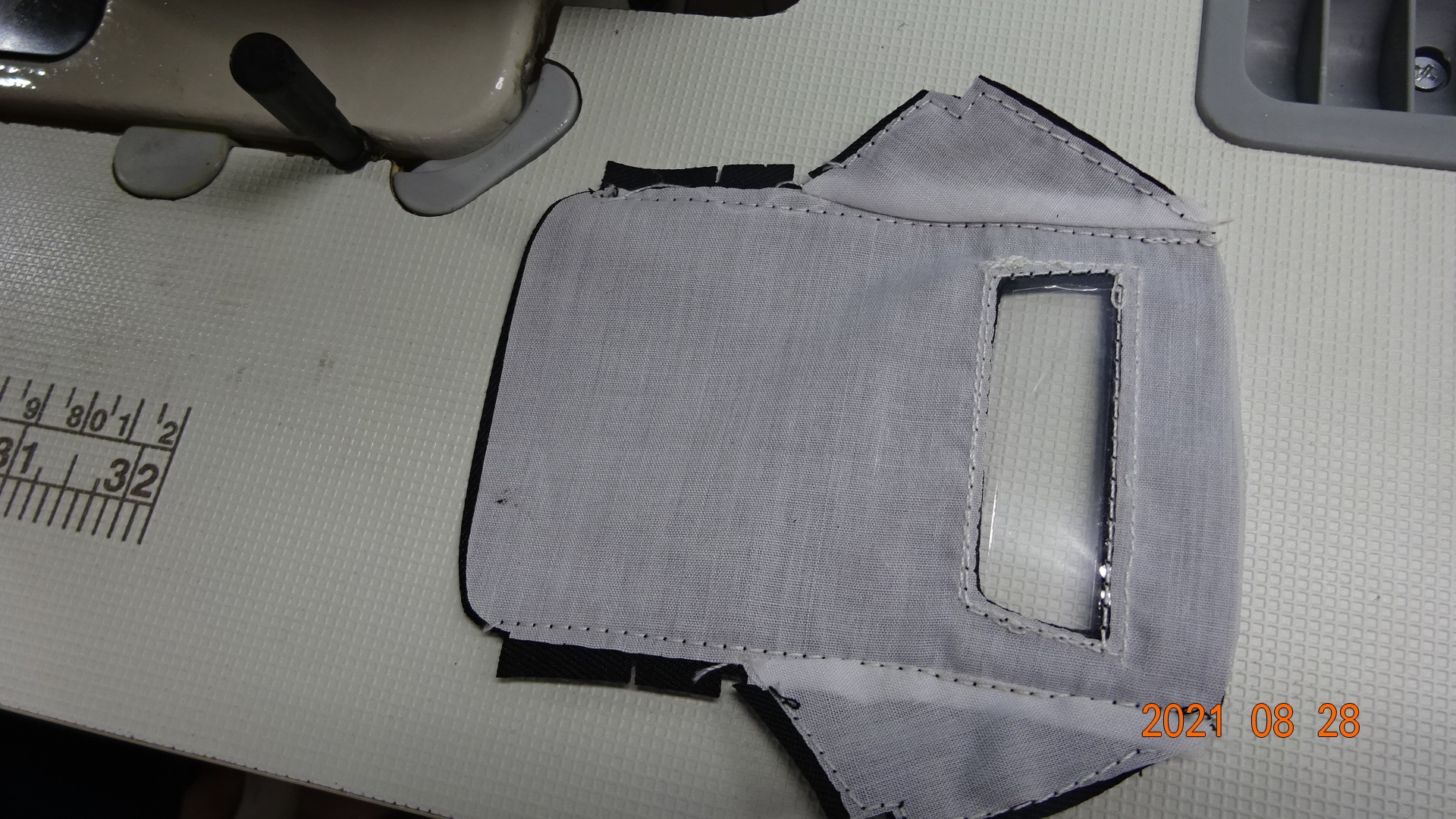

The alloy parts of the bracket were modified twice, and the sheet-metal parts, five times. As for the fabric canopy itself, it was modified so many times that sewing samples alone amounted to thousands. As a result of continuous modifications and efforts, the M-205 will finally go into production in September 2021.

The fabric canopy is made of six small cloths in two colors and a transparent film. The bracket consists of 3 zinc alloy parts and 72 hardware pieces, totaling 82 pieces. Your appraisal will be appreciated!

The following images are showing pre-final hand samples

An assembled soft-top frame

Installing a soft-top frame onto the car body

Check the proper fit of the soft-top frame

Functional test of the soft-top frame

Sewing the fabric soft-top

Inner look of the fabric soft-top

Exterior view of the fabric soft-top

Try fitting the fabric soft-top

Functional soft-top in its final stage